ToF 3D Sensors for Industrial Quality Inspection & Precision Automation

How Can ToF 3D Sensors Improve Industrial Quality Inspection and Precision Automation

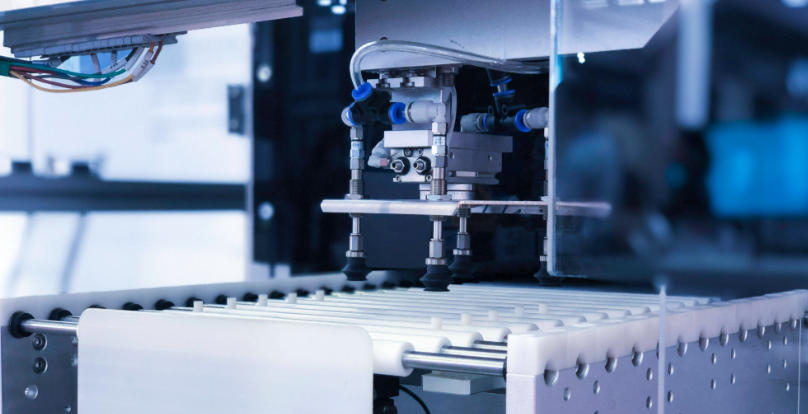

In modern manufacturing, the demand for high‑precision, high‑speed and automated quality inspection has become more critical than ever. Traditional contact measurement tools or 2D vision systems often struggle to keep pace. They can be slow, inconsistent, and prone to errors when detecting subtle defects or dimensional deviations. In response, ToF 3D sensors and ToF depth cameras have emerged as a powerful solution offering non‑contact, real‑time 3D depth sensing, high‑precision dimensional measurement, surface defect detection, and automated inspection compatible with smart factory automation.

Why Traditional Inspection Methods Fall Short

2D cameras only capture surface texture and color, lacking depth and spatial information, making it difficult to detect dents, bumps, misaligned holes, or subtle geometric deviations. Manual measurements are slow, labor-intensive, and suffer from human inconsistency. Contact-based measuring tools can disturb or damage delicate parts, and are impractical for high‑throughput production lines. These limitations make traditional inspection inadequate for modern manufacturing lines where speed, consistency, and precision are required.

What ToF Brings to Industrial Quality Inspection

ToF 3D sensors measure the flight time of light pulses to calculate distances and generate dense 3D point‑cloud data. Compared with 2D vision, ToF provides complete spatial coordinates plus depth information enabling:

-

High-precision dimensional and geometry measurement: length, width, height, angles, hole alignment, surface flatness, and geometric conformity measured in milliseconds per item

-

Surface defect detection and surface quality monitoring: scratches, dents, burrs, uneven coatings, welding irregularities, weld‑spot deviations, and other surface anomalies become visible in 3D depth data

-

Real-time inspection on high-speed production lines: fast frame rates and low latency suitable for automated inspection on conveyor belts or assembly lines enabling continuous quality control

-

Non-contact and robust operation: works well under variable lighting, in dusty or industrial environments, and avoids wear or damage to parts

This makes ToF a robust foundation for intelligent, automated, and scalable quality assurance in smart factories.

Typical Industrial Applications of ToF Inspection

Electronics and PCB Manufacturing

In electronics assembly lines, especially for PCBs, solder joints and tiny components demand micron‑level precision. ToF depth cameras can detect solder‑height variations, pin misalignment, uneven soldering surfaces, or subtle warping, reducing defect rates, rework, and improving yield consistency.

Automotive Parts and Mechanical Components

Automotive manufacturing involves many precision parts where even small geometric deviations can compromise safety or performance. ToF inspection can quickly detect misaligned holes, gaps, weld flaws, or dimensional deviations ensuring all parts meet design tolerances before assembly.

Surface Finish and Coating Quality Verification

In industries with metal stamping, molding, or surface coating, surface defects like dents, bumps, uneven coatings, or scratches can degrade product quality. ToF’s 3D depth sensing makes these defects visible and measurable enabling automated surface quality inspection and reducing reliance on manual visual inspection.

High-Speed Mass Production Lines

For high-volume production, ToF enables real-time, consistent inspection. Depth data can be fed into automated rejection systems or robotic manipulators to remove defective parts immediately, enabling a closed-loop quality control system, improving throughput, reducing manual labor, and cutting waste.

Advantages of ToF Over Laser Scanners or Structured Light

While laser scanning or structured-light 3D inspection methods also provide depth, TOF (Time-of-Flight) offers unique advantages:

-

Faster measurement and higher frame rate suitable for dynamic production lines

-

Better performance in challenging industrial conditions less affected by ambient light, reflections, or background textures ensuring stable measurements

-

Compact, low-power, and easier integration into automated production lines, robotics systems, and inspection stations avoiding bulky setups

ToF balances speed, precision, cost, and adaptability making it ideal for modern smart manufacturing.

Challenges and Considerations in Deploying ToF Inspection

Although powerful, deploying ToF-based quality inspection requires addressing technical challenges:

-

Complex surfaces and reflective materials: shiny metals, curved surfaces, or transparent parts can produce noisy or distorted depth data

-

Data processing load: high-density 3D point clouds require robust computing for real-time analysis and defect detection

-

Calibration and maintenance: sensor alignment, temperature, dust, ambient light, and vibration may affect accuracy; regular calibration and protective housing help maintain reliability

-

Integration with production systems: To enable automated rejection or feedback, ToF inspection systems must integrate with robotics, PLCs, conveyors, or manufacturing execution systems

When properly designed, these challenges can be managed, resulting in a highly reliable, automated, and precise quality control system.

The Future: ToF + AI + Smart Manufacturing for Zero-Defect Production

As sensor resolution improves and AI-driven point-cloud analysis advances, ToF-based inspection is evolving beyond simple pass/fail checks:

-

AI-based defect classification and predictive quality analysis detecting complex defects, predicting potential failures, and providing insights for process improvement

-

Closed-loop production optimization inspection data feeds back into machinery to adjust parameters in real time reducing waste and improving consistency

-

Digital twin and data-driven manufacturing depth data and inspection history build digital twins enabling traceability, quality tracking, and data-driven decision making

-

Scalable deployment across industries from automotive to electronics to metal machining and photovoltaics ToF inspection becomes a universal tool for smart, efficient, high-quality manufacturing

ToF 3D sensors transform quality inspection from a post-production bottleneck into a continuous, automated, data-driven process paving the way for high-efficiency, high-precision, and low-defect smart factories.

Conclusion

For manufacturers seeking to improve product quality, increase throughput, reduce waste, and move toward Industry 4.0 automation, ToF 3D sensors offer a comprehensive solution for automated, real-time, high-precision quality inspection and defect detection. By replacing or augmenting traditional 2D vision and contact measurement methods, ToF-based inspection systems deliver speed, consistency, and accuracy supporting the transition to intelligent, data-driven, and scalable manufacturing systems.

ToF is not just a sensor; it is a key enabler of precision, reliability, and smart automation in next-generation industrial quality control.

Synexens 3D Of RGBD ToF Depth Sensor_CS30

After-sales Service: Our professional technical support team specializes in TOF camera technology and is always ready to assist you. If you encounter any issues during the usage of your product after purchase or have any questions about TOF technology, feel free to contact us at any time. We are committed to providing high-quality after-sales service to ensure a smooth and worry-free user experience, allowing you to feel confident and satisfied both with your purchase and during product use.